The very first validation things to do focused the processes worried about generating these solutions; however, they promptly unfolded to associated processes and environmental management, media fill, tools sanitizing, and pure water generation.

Readings have to be taken about a wide functioning array for that most crucial functions, and all facts obtained has to be exhaustively analyzed.

Prosperous CPV supplies documentation that important top quality characteristics stay controlled all over the producing process and about its total lifecycle.

ICH guidelines prescribe that not less than nine determinations must be run over the assortment specified for your treatment. Values to be reported include things like conventional deviation, coefficient of variation (relative standard deviation), and self-assurance interval.

The 1st batch shall be dispatched after the completion of the 3rd batch of producing, testing, and review of benefits.

This document should have specifics of validation for being carried out, and the timeframes with the scientific tests to be executed. There should be distinct statements with regards to who is accountable for Each and every Component of the validation method.

Concurrent validation requires monitoring from the essential processing and tests methods for the in-process phase. It is nearly the same as possible validation apart from the company will promote the solutions created in the validation run, delivered they meet many of the pre-identified top quality demands.

Again, very similar tests will probably be finished for all the various parts of apparatus applied to organize our cake.

Now we’ll place a cake tin with Uncooked cake blend into the oven and Verify which the oven nonetheless performs as expected Which our cake cooks as predicted.

Routine tests of in-process supplies and click here remaining solution sampling (evaluating both equally in and amongst batches)

For Cost reduction: Mainly because of the streamlined validation process, there’s a reduction in the number of sampling and screening processes. website This results in less solution rejections and retesting, causing Value cost savings.

Likewise the bounds furnished in MPS for Hardness/thickness/ yields are indicative only and wish to ascertain for the duration of PV.

Complete the PV of only Mixing Procedure and decide the extent of validation study of other stages depending on the danger/effect evaluation.

Pharmaceutical producers have to verify their validation method addresses all of the significant areas of pharmaceutical processing. The major regions include:

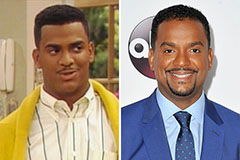

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Kane Then & Now!

Kane Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!